Helicopter

About this schools Wikipedia selection

SOS Children made this Wikipedia selection alongside other schools resources. A good way to help other children is by sponsoring a child

A helicopter (or chopper, helo or whirlybird) is a type of rotorcraft in which lift and thrust are supplied by rotors. This allows the helicopter to take off and land vertically, to hover, and to fly forwards, backwards, and laterally. These attributes allow helicopters to be used in congested or isolated areas where fixed-wing aircraft would usually not be able to take off or land. The capability to hover efficiently for extended periods of time allows a helicopter to accomplish tasks that fixed-wing aircraft and other forms of vertical takeoff and landing aircraft cannot perform.

The word helicopter is adapted from the French hélicoptère, coined by Gustave de Ponton d'Amecourt in 1861, which originates from the Greek helix/helik- (ἕλιξ) = "twisted, curved" and pteron (πτερόν) = "wing".

Helicopters were developed and built during the first half-century of flight, with the Focke-Wulf Fw 61 being the first operational helicopter in 1936. Some helicopters reached limited production, but it was not until 1942 that a helicopter designed by Igor Sikorsky reached full-scale production, with 131 aircraft built. Though most earlier designs used more than one main rotor, it is the single main rotor with anti-torque tail rotor configuration that has become the most common helicopter configuration. Tandem rotor helicopters are also in widespread use, due to their better payload capacity. Quadrotor helicopters and other types of multicopter have been developed for specialized applications.

History

The earliest references for vertical flight have come from China. Since around 400 BC, Chinese children have played with bamboo flying toys, and the 4th-century AD Daoist book Baopuzi (抱朴子 "Master who Embraces Simplicity") reportedly describes some of the ideas inherent to rotary wing aircraft:

| “ | Someone asked the master about the principles of mounting to dangerous heights and traveling into the vast inane. The Master said, "Some have made flying cars with wood from the inner part of the jujube tree, using ox-leather [straps] fastened to returning blades so as to set the machine in motion." | ” |

It was not until the early 1480s, when Leonardo da Vinci created a design for a machine that could be described as an "aerial screw", that any recorded advancement was made towards vertical flight. His notes suggested that he built small flying models, but there were no indications for any provision to stop the rotor from making the craft rotate. As scientific knowledge increased and became more accepted, men continued to pursue the idea of vertical flight. Many of these later models and machines would more closely resemble the ancient bamboo flying top with spinning wings, rather than Da Vinci's screw.

In July 1754, Mikhail Lomonosov demonstrated a small tandem rotor to the Russian Academy of Sciences. It was powered by a spring and suggested as a method to lift meteorological instruments. In 1783, Christian de Launoy, and his mechanic, Bienvenu, made a model with a pair of counter-rotating rotors, using turkey flight feathers as rotor blades, and in 1784, demonstrated it to the French Academy of Sciences. Sir George Cayley, influenced by a childhood fascination with the Chinese flying top, grew up to develop a model of feathers, similar to Launoy and Bienvenu, but powered by rubber bands. By the end of the century, he had progressed to using sheets of tin for rotor blades and springs for power. His writings on his experiments and models would become influential on future aviation pioneers. Alphonse Pénaud would later develop coaxial rotor model helicopter toys in 1870, also powered by rubber bands. One of these toys, given as a gift by their father, would inspire the Wright brothers to pursue the dream of flight.

In 1861, the word "helicopter" was coined by Gustave de Ponton d'Amécourt, a French inventor who demonstrated a small, steam-powered model. While celebrated as an innovative use of a new metal, aluminium, the model never lifted off the ground. D'Amecourt's linguistic contribution would survive to eventually describe the vertical flight he had envisioned. Steam power was popular with other inventors as well. In 1878 the Italian Enrico Forlanini's unmanned vehicle that was also powered by a steam engine, was the first of its type that rose to a height of 12 meters (40 ft), where it hovered for some 20 seconds after a vertical take-off. Emmanuel Dieuaide's steam-powered design featured counter-rotating rotors powered through a hose from a boiler on the ground.

In 1885, Thomas Edison was given US$1,000 by James Gordon Bennett, Jr., to conduct experiments towards developing flight. Edison built a helicopter and used the paper for a stock ticker to create guncotton, with which he attempted to power an internal combustion engine. The helicopter was damaged by explosions and one of his workers was badly burned. Edison reported that it would take a motor with a ratio of three to four pounds per horsepower produced to be successful, based on his experiments. Ján Bahýľ, a Slovak inventor, adapted the internal combustion engine to power his helicopter model that reached a height of 0.5 meters (1.6 ft) in 1901. On 5 May 1905, his helicopter reached four meters (13 ft) in altitude and flew for over 1,500 meters (4,900 ft). In 1908, Edison patented his own design for a helicopter powered by a gasoline engine with box kites attached to a mast by cables for a rotor, but it never flew.

First flights

In 1906, two French brothers, Jacques and Louis Breguet, began experimenting with airfoils for helicopters and in 1907, those experiments resulted in the Gyroplane No.1. Although there is some uncertainty about the dates, sometime between 14 August and 29 September 1907, the Gyroplane No. 1 lifted its pilot up into the air about two feet (0.6 m) for a minute. However, the Gyroplane No. 1 proved to be extremely unsteady and required a man at each corner of the airframe to hold it steady. For this reason, the flights of the Gyroplane No. 1 are considered to be the first manned flight of a helicopter, but not a free or untethered flight.

That same year, fellow French inventor Paul Cornu designed and built a Cornu helicopter that used two 20-foot (6 m) counter-rotating rotors driven by a 24 hp (18 kW) Antoinette engine. On 13 November 1907, it lifted its inventor to 1 foot (0.3 m) and remained aloft for 20 seconds. Even though this flight did not surpass the flight of the Gyroplane No. 1, it was reported to be the first truly free flight with a pilot. Cornu's helicopter would complete a few more flights and achieve a height of nearly 6.5 feet (2 m), but it proved to be unstable and was abandoned.

The Danish inventor Jacob Ellehammer built the Ellehammer helicopter in 1912. It consisted of a frame equipped with two counter-rotating discs, each of which was fitted with six vanes around its circumference. After a number of indoor tests, the aircraft was demonstrated outdoors and made a number of free take-offs. Experiments with the helicopter continued until September 1916, when it tipped over during take-off, destroying its rotors.

Early development

In the early 1920s, Argentine Raúl Pateras-Pescara de Castelluccio, while working in Europe, demonstrated one of the first successful applications of cyclic pitch. Coaxial, contra-rotating, biplane rotors could be warped to cyclically increase and decrease the lift they produced. The rotor hub could also be tilted forward a few degrees, allowing the aircraft to move forward without a separate propeller to push or pull it. Pateras-Pescara was also able to demonstrate the principle of autorotation. By January 1924, Pescara's helicopter No. 1 was tested but was found underpowered and could not lift its own weight. The British government funded further research by Pescara which resulted in helicopter No. 3, powered by a 250 hp radial engine which could fly for up to ten minutes.

On 14 April 1924 Frenchman Etienne Oehmichen set the first helicopter world record recognized by the Fédération Aéronautique Internationale (FAI), flying his quadrotor helicopter 360 meters (1,181 ft). On 18 April 1924, Pescara beat Oemichen's record, flying for a distance of 736 meters (nearly a half mile) in 4 minutes and 11 seconds (about 8 mph, 13 km/h), maintaining a height of six feet (1.8 meters). On 4 May, Oehmichen set the first 1 km closed-circuit helicopter flight in 7 minutes 40 seconds with his No. 2 machine.

In the USA, George de Bothezat built the quadrotor De Bothezat helicopter for the United States Army Air Service but the Army cancelled the program in 1924, and the aircraft was scrapped.

Albert Gillis von Baumhauer, a Dutch aeronautical engineer, began studying rotorcraft design in 1923. His first prototype "flew" ("hopped" and hovered in reality) on 24 September 1925, with Dutch Army-Air arm Captain Floris Albert van Heijst at the controls. The controls that Captain van Heijst used were Von Baumhauer's inventions, the cyclic and collective. Patents were granted to von Baumhauer for his cyclic and collective controls by the British ministry of aviation on 31 January 1927, under patent number 265,272.

Arthur M. Young, American inventor, started work on model helicopters in 1928 using converted electric hover motors to drive the rotor head. Young invented the stabilizer bar and patented it shortly after. A mutual friend introduced Young to Lawrence Dale, who once seeing his work asked him to join the Bell Aircraft company. When Young arrived at Bell he signed his patent over and began work on the helicopter. His budget was US$250,000 to build 2 working helicopters. In just 6 months they completed the first Bell Model 1, which spawned the Bell 30, later succeeded by the Bell 47.

In 1928, Hungarian aviation engineer Oszkár Asbóth constructed a helicopter prototype that took off and landed at least 182 times, with a maximum single flight duration of 53 minutes.

In 1930, the Italian engineer Corradino D'Ascanio built his D'AT3, a coaxial helicopter. His relatively large machine had two, two-bladed, counter-rotating rotors. Control was achieved by using auxiliary wings or servo-tabs on the trailing edges of the blades, a concept that was later adopted by other helicopter designers, including Bleeker and Kaman. Three small propellers mounted to the airframe were used for additional pitch, roll, and yaw control. The D'AT3 held modest FAI speed and altitude records for the time, including altitude (18 m or 59 ft), duration (8 minutes 45 seconds) and distance flown (1,078 m or 3,540 ft).

In the Soviet Union, Boris N. Yuriev and Alexei M. Cheremukhin, two aeronautical engineers working at the Tsentralniy Aerogidrodinamicheskiy Institut (TsAGI, Russian: Центра́льный аэрогидродинами́ческий институ́т (ЦАГИ), English: Central Aerohydrodynamic Institute), constructed and flew the TsAGI 1-EA single rotor helicopter, which used an open tubing framework, a four blade main rotor, and twin sets of 1.8-meter (6-foot) diameter anti-torque rotors: one set of two at the nose and one set of two at the tail. Powered by two M-2 power plants, up-rated copies of the Gnome Monosoupape rotary radial engine of World War I, the TsAGI 1-EA made several successful low altitude flights. By 14 August 1932, Cheremukhin managed to get the 1-EA up to an unofficial altitude of 605 meters (1,985 ft), shattering d'Ascanio's earlier achievement. As the Soviet Union was not yet a member of the FAI, however, Cheremukhin's record remained unrecognized.

Nicolas Florine, a Russian engineer, built the first twin tandem rotor machine to perform a free flight. It flew in Sint-Genesius-Rode, at the Laboratoire Aérotechnique de Belgique (now von Karman Institute) in April 1933, and attained an altitude of six meters (20 ft) and an endurance of eight minutes. Florine chose a co-rotating configuration because the gyroscopic stability of the rotors would not cancel. Therefore the rotors had to be tilted slightly in opposite directions to counter torque. Using hingeless rotors and co-rotation also minimised the stress on the hull. At the time, it was one of the most stable helicopters in existence.

The Bréguet-Dorand Gyroplane Laboratoire was built in 1933. It was a coaxial helicopter, contra-rotating. After many ground tests and an accident, it first took flight on 26 June 1935. Within a short time, the aircraft was setting records with pilot Maurice Claisse at the controls. On 14 December 1935, he set a record for closed-circuit flight with a 500-meter (1,600 ft) diameter. The next year, on 26 September 1936, Claisse set a height record of 158 meters (520 ft). And, finally, on 24 November 1936, he set a flight duration record of one hour, two minutes and 5 seconds over a 44 kilometer (27 mi) closed circuit at 44.7 kilometers per hour (27.8 mph). The aircraft was destroyed in 1943 by an Allied airstrike at Villacoublay airport.

Autogyro

Juan de la Cierva started building aircraft in Spain as early as 1912; in 1919 he started to consider the use of a rotor to generate lift at low airspeed, and eliminate the risk of stall. To achieve this, he used the ability of a lifting rotor to autorotate, whereby at a suitable pitch setting, a rotor will continue to rotate without mechanical drive, sustained by the torque equilibrium of the lift and drag forces acting on the blades. This phenomenon was already known, and was available as a safety feature to allow controlled descent in the event of engine failure. With de la Cierva's autogyro, the rotor was drawn through the air by means of conventional propeller, with the result that the rotor generated sufficient lift to sustain level flight, climb and descent.

Before this could be satisfactorily achieved, de la Cierva experienced several failures primarily associated with the unbalanced rolling movement generated when attempting take-off, due to dissymmetry of lift between the advancing and retreating blades. This major difficulty was resolved by the introduction of the flapping hinge. In 1923, de la Cierva's first successful autogyro was flown in Spain by Lt. Gomez Spencer. This pioneering work was carried out in de la Cierva's native Spain. In 1925 he brought his C.6 to England and demonstrated it to the Air Ministry at Farnborough, Hampshire. This machine had a four blade rotor with flapping hinges but relied upon conventional airplane controls for pitch, roll and yaw. It was based upon an Avro 504K fuselage, initial rotation of the rotor was achieved by the rapid uncoiling of a rope passed around stops on the undersides of the blades.

The Farnborough demonstration was a great success, and resulted in an invitation to continue the work in the UK. As a direct result, and with the assistance of the Scottish industrialist James G Weir, the Cierva Autogiro Company was formed the following year. From the outset de la Cierva concentrated upon the design and the manufacture of rotor systems, relying on other established aircraft manufacturers to produce the airframes, predominantly the A.V. Roe Company.

Avro-built C.8 was a refinement of the C.6, with the more powerful 180 hp Lynx radial engine, and several C.8s were built. The C.8R incorporated drag hinges, due to blade flapping motion causing high blade root stresses in the rotor plane of rotation; this modification, however, resulted in other problems such as ground resonance for which drag hinge dampers were fitted.

The resolution of these fundamental rotor problems opened the way for progressive improvements; confidence built up rapidly, and after several cross country flights a C.8L4 was entered for the 1928 Kings Cup Air Race. Although forced to withdraw, the C.8L4 subsequently completed a 4,800 km (3,000 mi) tour of the British Isles. Later that year it flew from London to Paris, extending the tour to include Berlin, Brussels and Amsterdam, thus becoming the first rotating wing aircraft to cross the English Channel.

A major problem with the autogyro was driving the rotor before takeoff. Several methods were attempted in addition to the coiled rope system, which could take the rotor speed to 50% of that required, at which point movement along the ground to reach flying speed was necessary, while tilting the rotor to establish autorotation.

Another approach was to tilt the tail stabiliser to deflect engine slipstream up through the rotor. The most acceptable solution was finally achieved with the C.19 Mk.4, which was produced in some quantities; a direct drive from the engine to the rotor was fitted, through which the rotor could be accelerated up to speed. The system was then declutched before the take-off run.

As de la Cierva's autogyros achieved success and acceptance, others began to follow and with them came further innovation. Most important was the development of direct rotor control through cyclic pitch variation, achieved initially by tilting the rotor hub and subsequently by the Austro-British engineer Raoul Hafner, by the application of a spider mechanism that acted directly on each rotor blade. The first production direct control autogyro was the C.30, produced in quantity by Avro, Liore et Olivier, and Focke-Wulf.

The production model, called the C.30A by Avro, was built under licence in Britain, France and Germany and was similar to the C.30P. The main alteration was a further increase in undercarriage track with revised strutting, the uppermost leg having a pronounced knee with wire bracing. There was additional bracing to the tailplane and both it and the fin carried small movable trimming surfaces. Each licensee used nationally built engines and used slightly different names. In all, 143 production C.30s were built, making it by far the most numerous pre-war autogyro.

Between 1933 and 1936, de la Cierva used one C.30A (G-ACWF) to perfect his last contribution to autogyro development before his death in a Douglas DC-2 (fixed wing) crash in late 1936. To enable the aircraft to take off without forward ground travel, he produced the "Autodynamic" rotor head, which allowed the rotor to be spun up by the engine in the usual way but to higher than take-off r.p.m at zero rotor incidence and then to reach operational positive pitch suddenly enough to jump some 20 ft (6 m) upwards.

Through creating his autogyros, Cierva established the foundational understanding of rotor dynamics and control, which was applicable to all rotorcraft, and led to the modern helicopter.

Birth of an industry

Heinrich Focke at Focke-Wulf had been licensed to produce the Cierva C.30 autogyro from 1933; Focke was inspired to design the world's first practical helicopter, the Focke-Wulf Fw 61, which first flew on 26 June 1936. The Fw 61 broke all of the helicopter world records in 1937, demonstrating a flight envelope that had only previously been achieved by the autogyro. Nazi Germany would use helicopters in small numbers during World War II for observation, transport, and medical evacuation. The Flettner Fl 282 Kolibri synchropter was used in the Mediterranean, while the Focke Achgelis Fa 223 Drache was used in Europe. Extensive bombing by the Allied forces prevented Germany from producing any helicopters in large quantities during the war.

In the United States, Russian-born engineer Igor Sikorsky and W. Lawrence LePage were competing to produce the U.S. military's first helicopter. Before the war, LePage had received the patent rights to develop helicopters patterned after the Fw 61, and built the XR-1. Meanwhile, Sikorsky had settled on a simpler, single rotor design, the VS-300, which turned out to be the first practical single lifting-rotor helicopter design and the best-flying one since the Soviet TsAGI 1-EA flown nearly a decade before. After experimenting with configurations to counteract the torque produced by the single main rotor, he settled on a single, smaller rotor mounted on the tailboom.

Developed from the VS-300, Sikorsky's R-4 became the first large-scale mass-produced helicopter with a production order for 100 aircraft. The R-4 was the only Allied helicopter to see service in World War II, primarily being used for rescue in Burma and Alaska, and other areas with harsh terrain. Total production would reach 131 helicopters before the R-4 was replaced by other Sikorsky helicopters such as the R-5 and the R-6. In all, Sikorsky would produce over 400 helicopters before the end of World War II.

As LePage and Sikorsky were building their helicopters for the military, Bell Aircraft hired Arthur Young to help build a helicopter using Young's two-blade teetering rotor design which used a weighted stabilizing bar placed at a 90° angle to the rotor blades. The subsequent Model 30 helicopter showed the design's simplicity and ease of use. The Model 30 was developed into the Bell 47, which became the first helicopter certificated for civilian use in the United States. Produced in several countries, the Bell 47 would stand as the most popular helicopter model for nearly 30 years.

Turbine age

In 1951, at the urging of his contacts at the Department of the Navy, Charles Kaman modified his K-225 synchropter with a new kind of engine, the turboshaft engine. This adaptation of the turbine engine provided a large amount of power to the helicopter with a lower weight penalty than piston engines, with their heavy engine blocks and auxiliary components. On 11 December 1951, the Kaman K-225 became the first turbine-powered helicopter in the world. Two years later, on 26 March 1954, a modified Navy HTK-1, another Kaman helicopter, became the first twin-turbine helicopter to fly. However, it was the Sud Aviation Alouette II that would become the first helicopter to be produced with a turbine-engine.

Reliable helicopters capable of stable hover flight were developed decades after fixed-wing aircraft. This is largely due to higher engine power density requirements than fixed-wing aircraft. Improvements in fuels and engines during the first half of the 20th century were a critical factor in helicopter development. The availability of lightweight turboshaft engines in the second half of the 20th century led to the development of larger, faster, and higher-performance helicopters. While smaller and less expensive helicopters still use piston engines, turboshaft engines are the preferred powerplant for helicopters today.

Uses

Due to the operating characteristics of the helicopter—its ability to takeoff and land vertically, and to hover for extended periods of time, as well as the aircraft's handling properties under low airspeed conditions—it has been chosen to conduct tasks that were previously not possible with other aircraft, or were time- or work-intensive to accomplish on the ground. Today, helicopter uses include transportation of people and cargo, military uses, construction, firefighting, search and rescue, tourism, medical transport, and aerial observation, among others.

A helicopter used to carry loads connected to long cables or slings is called an aerial crane. Aerial cranes are used to place heavy equipment, like radio transmission towers and large air conditioning units, on the tops of tall buildings, or when an item must be raised up in a remote area, such as a radio tower raised on the top of a hill or mountain. Helicopters are used as aerial cranes in the logging industry to lift trees out of terrain where vehicles cannot travel and where environmental concerns prohibit the building of roads. These operations are referred to as longline because of the long, single sling line used to carry the load.

The most grand-scale single non-combat helicopter operation in history was the disaster management operation following the 1986 Chernobyl nuclear disaster. Hundreds of pilots were involved in airdrop and observation missions, making dozens of sorties a day for several months.

Helitack is the use of helicopters to combat wildland fires. The helicopters are used for aerial firefighting (or water bombing) and may be fitted with tanks or carry helibuckets. Helibuckets, such as the Bambi bucket, are usually filled by submerging the bucket into lakes, rivers, reservoirs, or portable tanks. Tanks fitted onto helicopters are filled from a hose while the helicopter is on the ground or water is siphoned from lakes or reservoirs through a hanging snorkel as the helicopter hovers over the water source. Helitack helicopters are also used to deliver firefighters, who rappel down to inaccessible areas, and to resupply firefighters. Common firefighting helicopters include variants of the Bell 205 and the Erickson S-64 Aircrane helitanker.

Helicopters are used as air ambulances for emergency medical assistance in situations when an ambulance cannot easily or quickly reach the scene, or cannot transport the patient to a medical facility in time. Helicopters are also used when a patient needs to be transported between medical facilities and air transportation is the most practical method for the safety of the patient. Air ambulance helicopters are equipped to provide medical treatment to a patient while in flight. The use of helicopters as air ambulances is often referred to as MEDEVAC, and patients are referred to as being "airlifted", or "medevaced".

Police departments and other law enforcement agencies use helicopters to pursue suspects. Since helicopters can achieve a unique aerial view, they are often used in conjunction with police on the ground to report on suspects' locations and movements. They are often mounted with lighting and heat-sensing equipment for night pursuits.

Military forces use attack helicopters to conduct aerial attacks on ground targets. Such helicopters are mounted with missile launchers and miniguns. Transport helicopters are used to ferry troops and supplies where the lack of an airstrip would make transport via fixed-wing aircraft impossible. The use of transport helicopters to deliver troops as an attack force on an objective is referred to as Air Assault. Unmanned Aerial Systems (UAS) helicopter systems of varying sizes are being developed by companies for military reconnaissance and surveillance duties. Naval forces also use helicopters equipped with dipping sonar for anti-submarine warfare, since they can operate from small ships.

Oil companies charter helicopters to move workers and parts quickly to remote drilling sites located out to sea or in remote locations. The speed over boats makes the high operating cost of helicopters cost effective to ensure that oil platforms continue to flow. Various companies specialize in this type of operation.

Other uses of helicopters include, but are not limited to:

- Aerial photography

- Motion picture photography

- Electronic news gathering

- Reflection seismology

- Search and Rescue

- Tourism or recreation

- Transport

Design features

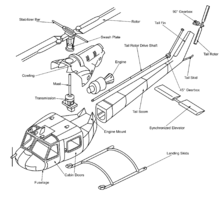

Rotor system

The rotor system, or more simply rotor, is the rotating part of a helicopter which generates lift. A rotor system may be mounted horizontally as main rotors are, providing lift vertically, or it may be mounted vertically, such as a tail rotor, to provide lift horizontally as thrust to counteract torque effect. The rotor consists of a mast, hub and rotor blades.

The mast is a cylindrical metal shaft which extends upwards from and is driven by the transmission. At the top of the mast is the attachment point for the rotor blades called the hub. The rotor blades are then attached to the hub by a number of different methods. Main rotor systems are classified according to how the main rotor blades are attached and move relative to the main rotor hub. There are three basic classifications: hingeless, fully articulated, and teetering, although some modern rotor systems use an engineered combination of these types.

Anti-torque features

Most helicopters have a single main rotor, but torque created as the engine turns the rotor causes the body of the helicopter to turn in the opposite direction to the rotor. To eliminate this effect, some sort of anti-torque control must be used.

The design that Igor Sikorsky settled on for his VS-300 was a smaller tail rotor. The tail rotor pushes or pulls against the tail to counter the torque effect, and has become the most common configuration for helicopter design.

Some helicopters use alternative anti-torque controls instead of the tail rotor, such as the ducted fan (called Fenestron or FANTAIL), and NOTAR. NOTAR provides anti-torque similar to the way a wing develops lift, through the use of a Coandă effect on the tailboom.

The use of two or more horizontal rotors turning in opposite directions is another configuration used to counteract the effects of torque on the aircraft without relying on an anti-torque tail rotor. This allows the power normally required to drive the tail rotor to be applied to the main rotors, increasing the aircraft's lifting capacity. Primarily, there are three common configurations that use the counter-rotating effect to benefit the rotorcraft. Tandem rotors are two rotors with one mounted behind the other. Coaxial rotors are two rotors that are mounted one above the other with the same axis. Intermeshing rotors are two rotors that are mounted close to each other at a sufficient angle to allow the rotors to intermesh over the top of the aircraft. Transverse rotors is another configuration found on tiltrotors and some earlier helicopters, where the pair of rotors are mounted at each end of the wings or outrigger structures. Quadrocopters see use mainly as model aircraft. Tip jet designs permit the rotor to push itself through the air, and avoid generating torque.

Engines

The number, size and type of engine(s) used on a helicopter determines the size, function and capability of that helicopter design. The earliest helicopter engines were simple mechanical devices, such as rubber bands or spindles, which relegated the size of helicopters to toys and small models. For a half century before the first airplane flight, steam engines were used to forward the development of the understanding of helicopter aerodynamics, but the limited power did not allow for manned flight. The introduction of the internal combustion engine at the end of the 19th century became the watershed for helicopter development as engines began to be developed and produced that were powerful enough to allow for helicopters able to lift humans.

Early helicopter designs utilized custom-built engines or rotary engines designed for airplanes, but these were soon replaced by more powerful automobile engines and radial engines. The single, most-limiting factor of helicopter development during the first half of the 20th century was that the amount of power produced by an engine was not able to overcome the engine's weight in vertical flight. This was overcome in early successful helicopters by using the smallest engines available. When the compact, flat engine was developed, the helicopter industry found a lighter-weight powerplant easily adapted to small helicopters, although radial engines continued to be used for larger helicopters.

Turbine engines revolutionized the aviation industry, and the turboshaft engine finally gave helicopters an engine with a large amount of power and a low weight penalty. Turboshafts are also more reliable than piston engines, especially when producing the sustained high levels of power required by a helicopter. The turboshaft engine was able to be scaled to the size of the helicopter being designed, so that all but the lightest of helicopter models are powered by turbine engines today.

Special jet engines developed to drive the rotor from the rotor tips are referred to as tip jets. Tip jets powered by a remote compressor are referred to as cold tip jets, while those powered by combustion exhaust are referred to as hot tip jets. An example of a cold jet helicopter is the Sud-Ouest Djinn, and an example of the hot tip jet helicopter is the YH-32 Hornet.

Some radio-controlled helicopters and smaller, helicopter-type unmanned aerial vehicles, use electric motors. Radio-controlled helicopters may also have piston engines that use fuels other than gasoline, such as Nitromethane. Some turbine engines commonly used in helicopters can also use biodiesel instead of jet fuel.

There are also human-powered helicopters.

Flight controls

A helicopter has four flight control inputs. These are the cyclic, the collective, the anti-torque pedals, and the throttle. The cyclic control is usually located between the pilot's legs and is commonly called the cyclic stick or just cyclic. On most helicopters, the cyclic is similar to a joystick. However, the Robinson R22 and Robinson R44 have a unique teetering bar cyclic control system and a few helicopters have a cyclic control that descends into the cockpit from overhead.

The control is called the cyclic because it changes the pitch of the rotor blades cyclically. The result is to tilt the rotor disk in a particular direction, resulting in the helicopter moving in that direction. If the pilot pushes the cyclic forward, the rotor disk tilts forward, and the rotor produces a thrust in the forward direction. If the pilot pushes the cyclic to the side, the rotor disk tilts to that side and produces thrust in that direction, causing the helicopter to hover sideways.

The collective pitch control or collective is located on the left side of the pilot's seat with a settable friction control to prevent inadvertent movement. The collective changes the pitch angle of all the main rotor blades collectively (i.e. all at the same time) and independently of their position. Therefore, if a collective input is made, all the blades change equally, and the result is the helicopter increasing or decreasing in altitude.

The anti-torque pedals are located in the same position as the rudder pedals in a fixed-wing aircraft, and serve a similar purpose, namely to control the direction in which the nose of the aircraft is pointed. Application of the pedal in a given direction changes the pitch of the tail rotor blades, increasing or reducing the thrust produced by the tail rotor and causing the nose to yaw in the direction of the applied pedal. The pedals mechanically change the pitch of the tail rotor altering the amount of thrust produced.

Helicopter rotors are designed to operate in a narrow range of RPM. The throttle controls the power produced by the engine, which is connected to the rotor by a fixed ratio transmission. The purpose of the throttle is to maintain enough engine power to keep the rotor RPM within allowable limits so that the rotor produces enough lift for flight. In single-engine helicopters, the throttle control is a motorcycle-style twist grip mounted on the collective control, while dual-engine helicopters have a power lever for each engine.

A Swashplate transmits the pilot commands to the main rotor blades for articulated rotors.

Flight

There are three basic flight conditions for a helicopter: hover, forward flight and the transition between the two.

- Hover

- Hovering is the most challenging part of flying a helicopter. This is because a helicopter generates its own gusty air while in a hover, which acts against the fuselage and flight control surfaces. The end result is constant control inputs and corrections by the pilot to keep the helicopter where it is required to be. Despite the complexity of the task, the control inputs in a hover are simple. The cyclic is used to eliminate drift in the horizontal plane, that is to control forward and back, right and left. The collective is used to maintain altitude. The pedals are used to control nose direction or heading. It is the interaction of these controls that makes hovering so difficult, since an adjustment in any one control requires an adjustment of the other two, creating a cycle of constant correction.

- Transition from hover to forward flight

- As a helicopter moves from hover to forward flight it enters a state called translational lift which provides extra lift without increasing power. This state, most typically, occurs when the airspeed reaches approximately 16–24 knots, and may be necessary for a helicopter to obtain flight.

- Forward flight

- In forward flight a helicopter's flight controls behave more like those of a fixed-wing aircraft. Displacing the cyclic forward will cause the nose to pitch down, with a resultant increase in airspeed and loss of altitude. Aft cyclic will cause the nose to pitch up, slowing the helicopter and causing it to climb. Increasing collective (power) while maintaining a constant airspeed will induce a climb while decreasing collective will cause a descent. Coordinating these two inputs, down collective plus aft cyclic or up collective plus forward cyclic, will result in airspeed changes while maintaining a constant altitude. The pedals serve the same function in both a helicopter and a fixed-wing aircraft, to maintain balanced flight. This is done by applying a pedal input in whichever direction is necessary to centre the ball in the turn and bank indicator.

Safety

Limitations

The main limitation of the helicopter is its low speed. There are several reasons a helicopter cannot fly as fast as a fixed-wing aircraft. When the helicopter is hovering, the outer tips of the rotor travel at a speed determined by the length of the blade and the RPM. In a moving helicopter, however, the speed of the blades relative to the air depends on the speed of the helicopter as well as on their rotational velocity. The airspeed of the advancing rotor blade is much higher than that of the helicopter itself. It is possible for this blade to exceed the speed of sound, and thus produce vastly increased drag and vibration. (See wave drag.)

Because the advancing blade has higher airspeed than the retreating blade and generates a dissymmetry of lift, rotor blades are designed to "flap" – lift and twist in such a way that the advancing blade flaps up and develops a smaller angle of attack. Conversely, the retreating blade flaps down, develops a higher angle of attack, and generates more lift. At high speeds, the force on the rotors is such that they "flap" excessively and the retreating blade can reach too high an angle and stall. For this reason, the maximum safe forward airspeed of a helicopter is given a design rating called VNE, Velocity, Never Exceed. In addition it is possible for the helicopter to fly at an airspeed where an excessive amount of the retreating blade stalls, which results in high vibration, pitch -up, and roll into the retreating blade.

During the closing years of the 20th century designers began working on helicopter noise reduction. Urban communities have often expressed great dislike of noisy aircraft, and police and passenger helicopters can be unpopular. The redesigns followed the closure of some city heliports and government action to constrain flight paths in national parks and other places of natural beauty.

Helicopters also vibrate; an unadjusted helicopter can easily vibrate so much that it will shake itself apart. To reduce vibration, all helicopters have rotor adjustments for height and weight. Blade height is adjusted by changing the pitch of the blade. Weight is adjusted by adding or removing weights on the rotor head and/or at the blade end caps. Most also have vibration dampers for height and pitch. Some also use mechanical feedback systems to sense and counter vibration. Usually the feedback system uses a mass as a "stable reference" and a linkage from the mass operates a flap to adjust the rotor's angle of attack to counter the vibration. Adjustment is difficult in part because measurement of the vibration is hard, usually requiring sophisticated accelerometers mounted throughout the airframe and gearboxes. The most common blade vibration adjustment measurement system is to use a stroboscopic flash lamp, and observe painted markings or coloured reflectors on the underside of the rotor blades. The traditional low-tech system is to mount coloured chalk on the rotor tips, and see how they mark a linen sheet. Gearbox vibration most often requires a gearbox overhaul or replacement. Gearbox or drive train vibrations can be extremely harmful to a pilot. The most severe being pain, numbness, loss of tactile discrimination and dexterity.

Hazards

As with any moving vehicle, unsafe operation could result in loss of control, structural damage, or loss of life. The following is a list of some of the potential hazards for helicopters:

- Settling with power, also known as a vortex ring state, is when the aircraft is unable to arrest its descent due to the rotor's downwash interfering with the aerodynamics of the rotor.

- Retreating blade stall is experienced during high speed flight and is the most common limiting factor of a helicopter's forward speed.

- Ground resonance affects helicopters with fully articulated rotor systems having a natural lead-lag frequency less than the blade rotation frequency.

- Low-G condition affects helicopters with two-bladed main rotors, particularly lightweight helicopters.

- Dynamic rollover in which the helicopter pivots around one of the skids and 'pulls' itself onto its side.

- Powertrain failures, especially those that occur within the shaded area of the height-velocity diagram.

- Tail rotor failures which occur from either a mechanical malfunction of the tail rotor control system or a loss of tail rotor thrust authority, called Loss of Tail-rotor Effectiveness (LTE).

- Brownout in dusty conditions or whiteout in snowy conditions.

- Low Rotor RPM, or rotor droop, in which the engine cannot drive the blades at sufficient RPM to maintain flight.

- Rotor Overspeed, which can over-stress the rotor hub pitch bearings (Brinelling) and, if severe enough, cause blade separation from the aircraft.

- Wire and tree strikes due to low altitude operations and take-offs and landings in remote locations.

- Controlled flight into terrain in which the aircraft is flown into the ground unintentionally due to lack of situational awareness.

Deadliest crashes

- 2002: a Mil Mi-26 was shot down over Chechnya; 127 killed.

- 1997: two Israeli Sikorsky CH-53 Sea Stallions collided over Israel; 73 killed.

- 14 December 1992: despite being heavily escorted, a Russian Army Mil Mi-8 was shot down by Georgian forces in Abkhazia using SA-14 MANPADs, with the loss of three crew members and 58 passengers composed of mainly Russian refugees.

- 4 October 1993: Russian forces shot down a Georgian Mi-8 transporting 60 refugees from eastern Abkhazia; all on board were killed.

- 10 May 1977: an Israeli CH-53 crashed near Yitav in the Jordan Valley; 54 killed.

- 11 September 1982: a U.S. Army Boeing CH-47 Chinook crashed at an air show in Mannheim, Germany; 46 killed.

- 1986: a Boeing 234LR Chinook operated by British International Helicopters crashed in the Shetland Islands; 45 killed.

- 1992 Azerbaijani Mil Mi-8 shootdown: 44 killed.

- 2009 Pakistan Army Mil Mi-17 crash: 41 killed.

- 2011: a CH-47 Chinook was shot down in Afghanistan: 38 killed.

- 26 January 2005: An USMC Sikorsky CH-53E Super Stallion crashed near Ar Rutbah, Iraq killing all 31 service members on board.

World records

| Record type | Record | Helicopter | Pilot(s) | Date | Location | Note | Reference |

|---|---|---|---|---|---|---|---|

| Speed | 400.87 km/h (249.09 mph) | Westland Lynx | John Trevor Egginton (UK) | 11 August 1986 | England, UK | ||

| Distance without landing | 3,561.55 km (2,213.04 mi) | Hughes YOH-6A | Robert G. Ferry (USA) | 6 April 1966 | USA | ||

| Around-the-world speed | 136.7 km/h (84.9 mph) | Agusta A109S Grand | Scott Kasprowicz (USA) | August 2008 | From and to New York via Europe, Russia, Alaska, Canada |

No in-flight refueling | |

| Highest level flight altitude | 11,010 m (36,120 ft) | Sikorsky CH-54 Tarhe | James K. Church | 4 November 1971 | USA | ||

| Altitude with 40- tonne payload | 2,255 m (7,398 ft) | Mil V-12 | Vasily Kolochenko, et al. | 6 August 1969 | Soviet Union | ||

| Highest takeoff (turbine) | 8,848 m (29,029 ft) | Eurocopter AS350 | Didier Delsalle | 14 May 2005 | FRA | Mount Everest (Nepal) | |

| Highest takeoff (piston) | 4,300.7 m (14,110 ft) | Robinson R44 | Mark Young | 12 October 2009 | USA | Pike's Peak, Colorado |